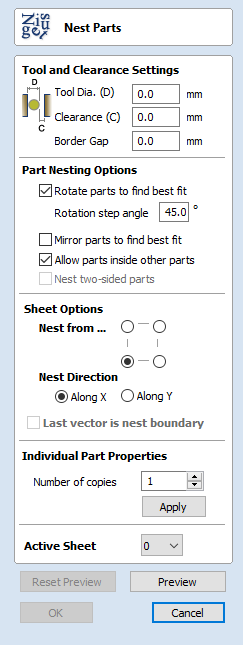

Nest Parts

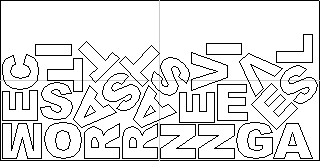

The Nesting tool will automatically fit vector shapes within the user defined area in the most efficient way it can calculate (based on the user defined parameters). By default the area the vectors will be fitted is the current Job Size but it is also possible to select a vector as the nesting area. This is a powerful way to optimize material usage and increase toolpath efficiency when laying out and cutting a number of shapes.

Object Selection

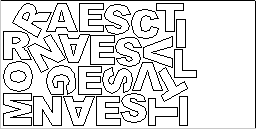

The Nesting tool allows you to select open vectors, closed vectors, text and components.

Once selected the objects will form parts, with part outer boundary highlighted with a thicker line.

The basis for forming parts is overlapping. If selected object contains another or overlaps with it they will be considered the same part.

Note

Currently it is not possible to nest components and other objects at the same time.

Tool and Clearance Settings

The settings in this section of the form will determine the spacing which will be left between each of the nested vectors and also control how close they are to the edge of your nesting area.

Tool Dia. (D)

Enter the diameter of the tool that you will be using to Profile (cut-out) the vectors you are nesting. This is the minimum distance that will be left between shapes once they are nested.

Clearance (C)

The Clearance value will be combined with the specified Tool Diameter to create the final minimum spacing between the nested shapes. For example a Clearance of 0.05 inches combined with a Tool Diameter of 0.25 inches would create a minimum spacing gap of 0.3 inches (0.05 + 0.25 = 0.3).

Border Gap

The Border Gap value is applied to the edge of the area which is being used to nest the vectors into. It will be added to the Clearance value around the edge of this shape to create the minimum distance that parts will be nested in respect to the nesting boundary.

Part Nesting Options

The options in this area of the form will all directly affect how many parts or how efficiently it is possible for the software to fit shapes into the defined nesting area.

Rotate Parts to find best fit

Checking ✓ this option will allow the software to rotate the selected vectors in order to try and better fit them. The increments of rotation the software will use is based on the Rotation step angle.

Mirror parts to find best fit

Checking ✓ this option will allow the nesting to mirror (flip) the vectors in order to try and more efficiently nest the selected shapes. This should only be checked ✓ if the direction the parts are cut in is not important.

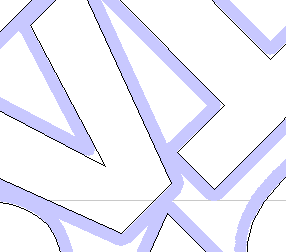

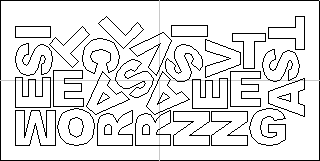

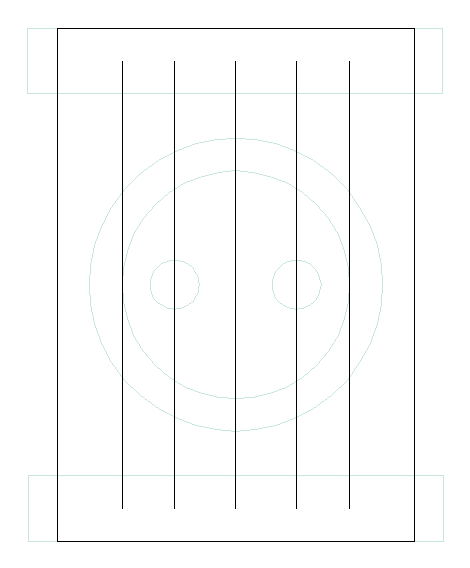

Allow parts inside other parts

Checking ✓ this option will allow the software to nest within the internal areas of shapes that have gaps in the middle.

When this option is active, the internal areas that will be considered in nesting will be highlighted.

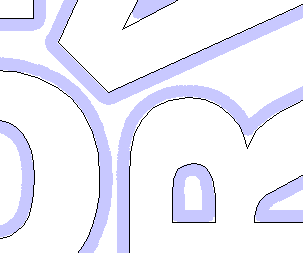

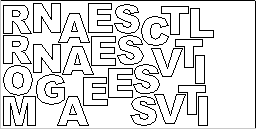

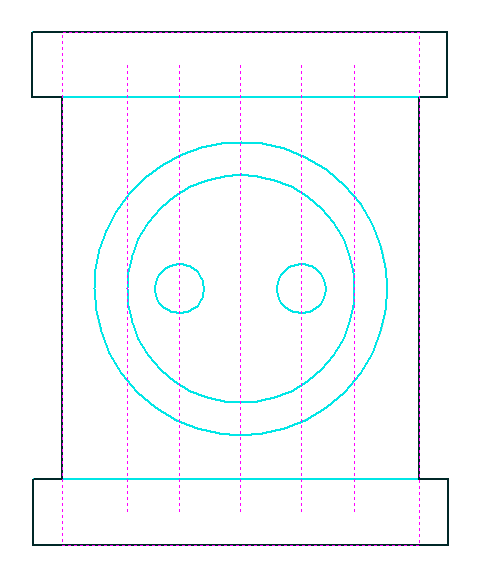

Nest two-sided parts

This option is only available for double-sided projects and allows nesting on both sides simultaneously. When this option is active, any visible objects on the other side will be included, if they intersect with objects selected on active side.

When using this mode it is recommended to perform selection on the side that contains cut-out contours.

When part is selected, the included vectors on the other side will be highlighted as can be seen below.

Sheet Options

Nest From

This area of the form is used to define which corner the nesting will start in. There are four options which can be selected from the options in the form.

Nest Direction

The options in this area of the form are used to select how the parts will progress as they are positioned within the sheet. The best way to think of this (for the purposes of this section) is that they 'pour' out of the selected corner filling the sheet in one axis then advancing along the other defined axis (X or Y) .

Last vector is nest boundary

Checking ✓ this option means the last vector selected will be used as the boundary for the nesting area. This can be useful if you need to define a non-rectangular shape to Nest Parts into, such as large off-cuts from a previous job. It's important to note that using this option will not respect the currently defined Job Area if the selected boundary vectors goes outside of it.

Note

If you need to represent a sheet with holes or other features which can't be represented with a single selected vector as the new boundary it is possible to also use a Grouped vector for the last selected item then the shapes will be nested within the spaces in this.

Individual Part Properties

If you want more than one incidence of a particular item then select it from the 2D view. In the box where it says Number of Copies enter as many copies as you want and hit and the selected vectors will be marked with a green number indicating how many copies of that item will be made when they are nested. Different shapes or groups of shapes can be assigned different numbers of copies. To stop an item being copied multiple times just set the Number of Copies back to 1 and click .

Active Sheet

This option lets you choose which Sheet of vectors is currently active, either for editing or applying toolpaths onto.